Grain Trailer

Built tough for demanding conditions, these trailers are your robust solution for industrial haulage.

Click HereTypes of Grain Trailers

side wall trailer

Side wall trailer is a commonly used type of semi-trailer for cargo transportation. It is characterized by openable side walls on both sides and at the rear to facilitate cargo loading and unloading.

| Condition | New |

|---|---|

Empty weight | 7500kgs |

Capacity | 60000kgs |

Suspension | air/spring suspension |

Feature | Carry bulk cargo |

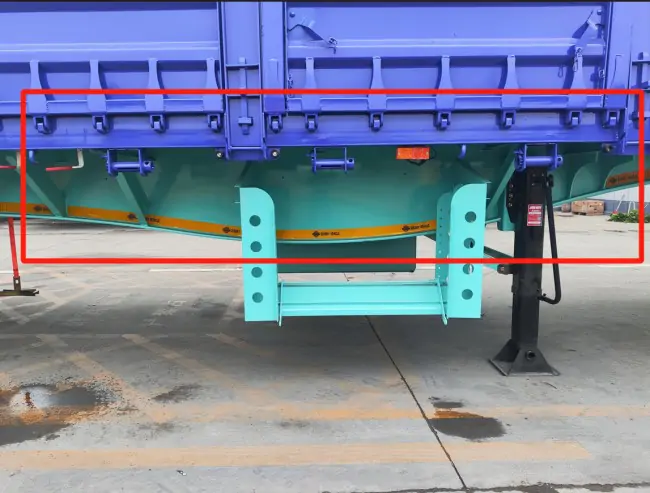

henred-type sideboard trailer

Henred-type sideboard trailer is a popular and versatile means of transport in the logistics and transportation industry. The small door on the side is designed to facilitate direct loading and unloading of grains.

| Condition | New |

|---|---|

Empty weight | 7500kgs |

Capacity | 60000kgs |

Suspension | air/spring suspension |

Feature | Carry bulk cargo |

Request your Grain Trailers quote today

Sunsky Grain Trailers Advantage

Enhanced suspension system boosts container torsion resistance, prolonging its lifespan and improving durability.

Our columns to flip downwards, significantly enhancing loading and unloading convenience and overall operational efficiency.

Grain Trailers

Frequently asked questions

Grain trailers are semi-trailers designed specifically for the efficient and safe transportation of bulk grain and similar agricultural products. Unlike regular bulk trailers (such as flatbed trailers or dump trucks), grain trailers are usually equipped with a unique side door unloading system that allows the cargo to be quickly and completely discharged through a small door designed on the side, directly into an underground receiving tank or conveyor system. This design minimizes unloading time, manpower requirements and material loss, ensures the cleanliness of the grain, and is an ideal tool for connecting farms, granaries, processing plants and ports.

Our grain haulers take into account durability and hygiene standards in material selection. The body is usually constructed of high-strength steel to cope with rugged road conditions and daily wear and tear; for customers who need higher load capacity and lighter weight, we provide high-quality aluminum alloy body options, which can not only increase payload, but also enhance corrosion resistance, especially for some wet agricultural products. Internal welding points and surface treatments are optimized to ensure smoothness, no gaps, and easy cleaning, effectively preventing grain residue and cross contamination, and meeting strict food transportation hygiene requirements.

Transporting bulk grain requires excellent stability and safety, and our **Bulk Grain Carrier has fully considered this. We use an optimized chassis structure and advanced suspension systems (such as air suspension or heavy mechanical suspension) to adapt to the center of gravity changes that may occur during the transportation of grain and minimize shaking. The interior design of the carriage is designed to ensure that the cargo is evenly distributed after loading to prevent eccentric loading. In addition, the high-strength side panels and top tarpaulin can effectively prevent grain from spilling during driving, while protecting the grain from external environmental factors (such as rain and dust), ensuring that the cargo is delivered intact.

Grain trailers play an irreplaceable role in several key scenarios:

Farm to granary/processing plant: This is its most important use, transporting harvested corn, wheat, soybeans, etc. directly from the field to storage warehouses or primary processing plants.

Feed and fertilizer transportation: They are also widely used to transport bulk animal feed, fertilizers and seeds and other agricultural inputs.

Biofuel industry: In bioethanol and biodiesel production, used to transport raw materials such as corn or rapeseed.

Port transshipment: In port areas, grain trailers are used to transfer bulk grain from rail or barge to export vessels or temporary storage facilities.

Construction materials: In some cases, it can also be used to transport dry, granular, non-corrosive construction materials. Its efficient unloading capacity makes it an ideal choice for bulk cargo transportation.

To ensure your Grain Hopper Trailer operates efficiently and for a long time, regular maintenance is essential:

Cleaning: Clean the interior of the carriage thoroughly after each transport of different types of grain to avoid cross contamination and hardening of residues.

Bottom Slide Valve and Mechanism Inspection: Regularly check the opening and closing mechanism, seals and lubrication points of the bottom slide valve to ensure smooth unloading without binding.

Suspension and Braking System: Check tire wear, air pressure, bearing lubrication, brake pads and air system according to manufacturer's recommendations to ensure safe driving.

Structural Integrity: Check the frame, side panels and hopper for cracks, deformation or corrosion, especially welding points.

Twist Locks and Top Hatches: Make sure all locks and top hatches are tightly sealed to prevent leakage and water ingress.

Hydraulic System (if applicable): Check the hydraulic oil level and lines for leaks. Following these maintenance guidelines will greatly extend the life of the trailer and reduce operating costs.

Connect with us

Ready to partner? We’re convinced Sunsky Vehicle is your best choice! Reach out through the form or by phone.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.