bulk cement trailer

Conquer bulk powder logistics with our Bulk Cement Trailers. Designed for safe, precise, and contamination-free delivery of cement and dry materials, optimizing your supply chain.

What is bulk cement trailer?

A bulk cement trailer, commonly known as a cement bulker, pneumatic trailer, or dry bulk trailer, is a specialized semi-trailer designed for the efficient and clean transportation of powdered and granular materials in bulk. Unlike liquid tankers, its enclosed, pressurized tank is built to handle dry goods like cement, fly ash, lime, and various powders. The defining feature is its pneumatic discharge system, which uses compressed air from an onboard or external compressor to fluidize the material and push it out through discharge pipes, allowing for dust-free and precise unloading directly into silos or storage facilities.

cement bulk trailer application scenarios

Bulk cement trailers are crucial for the efficient supply chains of industries relying on large volumes of dry, powdered materials. Their sealed, pneumatic discharge system ensures material integrity and cleanliness.

Construction Industry: Primarily used to transport bulk cement from cement plants to concrete batching plants, precast concrete factories, and large construction sites for roads, bridges, and buildings.

Chemical & Industrial Manufacturing: Transporting various dry chemical powders, plastic pellets, or granular raw materials that require sealed, pneumatic delivery.

Food Industry (Specialized): While primarily for construction materials, specialized, food-grade versions (often called powder tankers) transport flour, sugar, or starch in bulk, maintaining hygiene standards.

Agricultural Sector: Delivering bulk fertilizers or animal feed in large quantities to farms.

Building Materials Supply: Delivering fly ash, lime, and other binding agents or additives to various building material manufacturers.

Mining Operations: Hauling pulverized lime or other dry chemicals used in mineral processing or ground stabilization within mining facilities.

Standard configuration

-

SUNSKY axle

-

12R22.5 Tires

-

LED light system

-

Carbon Steel material

-

surface paint process

-

Leaf spring suspension

-

toolbox

Customizable options

-

Effective volume

-

payload

-

ABS

-

landing gear

-

Suspension type

-

Tire size

-

BPW/Triangle/FUWA axles as needed

Looking for some new designs ?

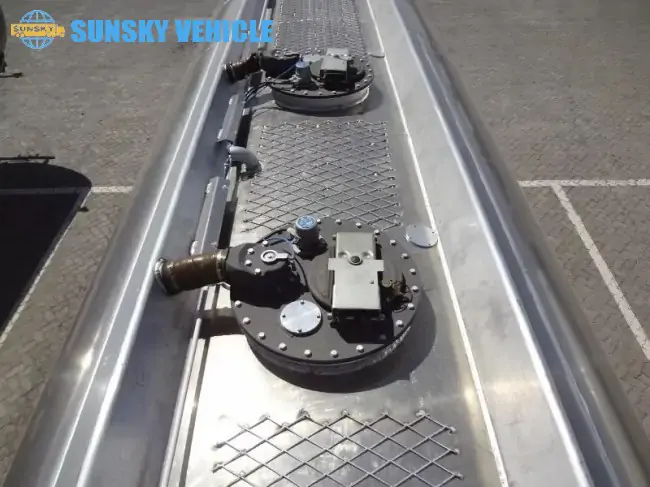

bulk cement semi trailer detail design

Optimized Tank Shape & Material: Our cement bulkers feature a precisely engineered tank design, typically cylindrical or V-shaped, crafted from high-strength steel or lightweight aluminum. The internal angles and smooth surfaces are optimized for complete and efficient material discharge, preventing residual buildup and ensuring longevity against abrasive powders.

Advanced Pneumatic Discharge System: Equipped with a powerful onboard air compressor, fluidizing air pads, and robust discharge piping, our pneumatic trailers ensure rapid, efficient, and dust-free unloading. This system creates an air cushion to fluidize the powder, allowing it to flow smoothly and completely, minimizing residue and maximizing delivery speed.

Secure & Sealed Loading Hatches: Multiple large-diameter manholes or loading hatches are strategically placed on top of the tank, featuring robust, airtight seals and locking mechanisms. This design ensures quick, clean, and secure top-loading of bulk powders, preventing contamination during loading and ensuring material integrity during transit.

Robust Chassis & Suspension: The trailer is built on a heavy-duty steel chassis, paired with a multi-axle configuration and advanced suspension (air-ride or mechanical). This ensures exceptional stability, even weight distribution, and reduced road shock, crucial for safely transporting dense, shifting powdered materials over long distances and varied terrains.

Integrated Safety & Control Features: Designed with essential safety devices, including pressure relief valves to prevent over-pressurization, a precise pressure gauge, and external emergency shut-off valves for rapid system control. These features, combined with anti-lock braking systems (ABS), enhance operational safety and compliance during bulk powder transport.

Video of cement bulk trailer

45CBM Bulk Cement Trailer

3-axle cement bulk trailer

bulk cement tank trailer

aluminum bulk cement tank trailer

The trailer type you are looking for is not found

FAQ

What types of dry bulk materials can a bulk cement trailer effectively transport besides cement?

A bulk cement trailer, often referred to as a dry bulk trailer or powder tanker, is highly versatile and can effectively transport a wide range of dry, powdered, or granular materials. Beyond cement, common cargo includes fly ash, lime powder, various types of sand (e.g., frac sand), flour, feed grains, sugar, plastic pellets, and certain chemical powders. Its sealed pneumatic discharge system makes it ideal for any material that needs protection from moisture and requires clean, dust-free offloading.

How does the pneumatic discharge system in a cement bulker actually work?

The pneumatic discharge system in a cement bulker works by using compressed air. An onboard or external air compressor generates high-pressure air, which is directed into aerating pads or lines inside the bottom of the tank. This air fluidizes the dry powder, transforming it into a semi-liquid state, reducing friction. The pressurized air then pushes the fluidized material out through the discharge pipes, allowing for rapid, controlled, and dust-free unloading directly into silos or storage containers without the need for manual handling.

What are the key advantages of using a dry bulk trailer over bagged transport for cement?

Using a dry bulk trailer offers significant advantages over bagged transport for cement and other powders. It eliminates the need for expensive packaging, reduces labor costs for loading and unloading, and minimizes material waste due to bag breakage. Furthermore, cement tankers provide a sealed, dust-free environment, preventing contamination and environmental pollution during transport and discharge, leading to greater efficiency, cost savings, and improved environmental compliance in bulk powder transport logistics.

What maintenance is critical for preventing clogging and ensuring efficient discharge in a powder tanker?

Critical maintenance for preventing clogging and ensuring efficient discharge in a powder tanker involves regular cleaning of the interior tank and discharge lines to remove residual material buildup. Inspection of the air pads for wear or damage, and ensuring the air compressor functions optimally, are vital for effective fluidization. Checking all valves, hoses, and manhole seals for leaks, and lubricating moving parts, are also essential for maintaining system integrity and preventing costly clogs or discharge failures in bulk cement transport equipment.

Are there different capacity options and configurations for bulk cement trailers?

Yes, bulk cement trailers offer various capacity options and configurations to suit diverse operational needs. Capacities typically range from 25 to 60 cubic meters (or more), influencing the overall length and number of axles. Configurations might include different discharge angles for specific materials, varying numbers of manholes, and options for integrated compressors or relying on external air sources. Custom designs can also feature different material choices (steel vs. aluminum) and specialized safety features to comply with specific regional or cargo requirements for cement transport solutions.

What safety features are essential for a pneumatic bulk trailer handling pressurized dry goods?

Essential safety features for a pneumatic bulk trailer handling pressurized dry goods include robust pressure relief valves to prevent over-pressurization during loading or discharge, precise pressure gauges for real-time monitoring, and automatic emergency shut-off valves. High-quality air filters prevent contamination of the pneumatic system, and secure, tamper-proof manholes ensure cargo integrity. Furthermore, anti-lock braking systems (ABS) and electronic stability control (ESC) enhance road safety, crucial for any bulk powder transport unit.

How does the choice of material (steel vs. aluminum) impact a cement tanker's performance and cost?

The choice of material for a cement tanker impacts performance and cost significantly. Steel cement tankers are generally more robust, offering higher durability and impact resistance, often at a lower initial cost. However, they are heavier, potentially limiting payload. Aluminum cement tankers are considerably lighter, allowing for greater payload capacity per trip, which translates to improved fuel efficiency and reduced operating costs over time. While typically having a higher initial price, their corrosion resistance and enhanced payload often provide a superior long-term return on investment for bulk cement transport.

Connect with us

Ready to partner? We’re convinced Sunsky Vehicle is your best choice! Reach out through the form or by phone.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.