PRODUCT

PRODUCT CATEGORIES

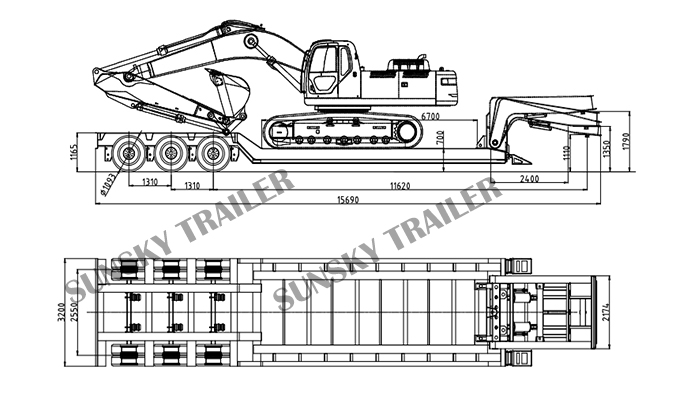

Detachable Gooseneck Low Bed Trailer

SUNSKY trailer is focus on semi trailers,tank trailers,flatbed trailers,dump trailers with 30 years experience.2,3,4 axles with different capacity and deadweight.Customizable.

- PRODUCT DETAILS

The gooseneck removable low bed trailer is a branch of the construction machinery transport vehicle, which is mainly used for loading the construction machinery with small climbing angle. Due to the limitation of the rear axle and tires, the gooseneck is designed to be loaded from the front, and the gooseneck needs to be removed during loading. The connection structure between the gooseneck and the frame in the picture is clear, and the design is reasonable, which can be referred to.

Low bed semi-trailer is usually used to transport heavy vehicles (such as tractors, buses and special vehicles), rail vehicles, mining machinery, forestry machinery, agricultural machinery, such as the harvester, wheeled tractor, conveyor, engineering machinery, such as excavators, bulldozers, loaders, paver, cranes, etc, and other heavy goods, the lower its center of gravity, The better the stability and safety, the better the ability to move super-high cargo and through overhead barriers.

Low bed semi-trailer usually adopts concave beam frame, that is, the front section of the frame is connected to the gooseneck end of the traction pin and traction saddle on the tractor, the middle section is the cargo platform, and the rear section is the wheel frame. When loading mechanical equipment to the fixed gooseneck low bed semi-trailer, the mechanical equipment is usually loaded from the rear end of the semi-trailer, that is, by moving the mechanical equipment from the rear wheel frame or removing the wheel, and then fixing the mechanical equipment on the semi-trailer. Since the rear wheel frame is always higher than the cargo table, there are many defects in this way of loading.

⬛ SPECIFICATION

|

3 Axle 70 Tons detachable lowbed trailer |

|

| Dimension(L*W*H): | About 15690*3200*1800mm |

| Cargo platform size: | 6700*3200 mm |

| No. of axle: | 3 |

| Kingpin: | 3.5inch, 90# bolt in type |

| Payload: | 70 Tons |

| Tire size: | 12R22.5 (12 sets) |

| Rim size: | 9..00-22.5 (12 sets) |

| Axle: | 16 Tons, 3 Axle |

| Suspension: | Spring suspension |

| Brake system: | WABCO brand Re-6 emergency relay valve |

| Electric system: | One unit of 24V 7-pin ISO standard socket; with brake light, turn light, reverse light, side light, reflector, fog light; one set of 6-pin standard cable |

| Painting: | Two coat of anti-corrosion prime; one coat of finish painting |

| Accessory: | With diesel engine power pack and removable hydraulic gooseneck |

| Loading/Shipping idea: | Load by RoRo or bulk ship |

|

We can build the trailers according to customer’s design, requirement and budget. Different specification cost different price. |

|

First of all, when moving equipment from the rear wheel frame, a suitable ramp or ladder should be provided, and if necessary, a considerable length of ladder should be required to provide a slope suitable for the heavy machinery equipment. Loaded in this way, machinery and equipment are liable to slip off the ladder or tip over. When it leaves the gangplank, it is also easy to fall to the semi-trailer cargo platform, which produces too large impact load on the cargo platform. If the wheels are removed and the semitrailer body touches the ground to load mechanical equipment, then the wheels must be returned to a winch or lifting machine to lift the body to a height where the wheels can be reinstalled. Therefore, additional equipment is needed.Such operations are time consuming and can be dangerous. In addition to loading from the rear end of the low flatbed semi-trailer, it can be loaded from both sides. There are also many drawbacks to loading from both sides. For example, loading and unloading operations require wide operating areas that are difficult to achieve under normal operating conditions.

In addition, from either side loading and unloading is only suitable for certain goods, such as caterpillar machinery that can walk on their own (loading and unloading process generally need to use sleeper to provide appropriate slope, and easily damaged when mechanical equipment on the cargo to double loading or appear the phenomenon such as partial load) or overload ultra high goods (the lifting height required for loading and unloading cargo is limited). Due to the potential disadvantages of the above loading and unloading methods, front-loading and unloading methods are usually adopted abroad to eliminate these problems, and front-loading and unloading methods have become the preferred transportation methods of SUNSKY machinery and equipment transportation.

Detachable gooseneck low bed semi-trailer, the gooseneck can be completely separated from the semi-trailer, once the front end of the semi-trailer is lowered to contact the ground, but it is still connected with the rear end of the tractor. After loading or unloading, the tractor pulls the gooseneck back and aligns it with the front of the semitrailer. The semitrailer reconnects with the gooseneck and returns to the transport state.

Classification of removable gooseneck low flatbed semitrailers

North America as early as the end of the 1930s has developed a Detachable gooseneck low bed semi-trailer, but the structure of the trailer is simple, its removable gooseneck can not be adjusted up and down, it is difficult to align with the semi-trailer and reconnect. By the early 1940s, there appeared the low flatbed semi-trailer which could adjust the gooseneck up and down by the winch and rope installed on the tractor so that the gooseneck could be aligned with the semi-trailer. Its disadvantage was that it needed special equipment which was not needed for other functions provided by the tractor.

By the late 1940s, with the development and application of the hydraulic system, the removable gooseneck low bed semi-trailer also began to use the hydraulic system to provide the power needed for the gooseneck disassembly. Usually, the tractor provides hydraulic power equipment, gooseneck with hydraulic system, but this way also requires the tractor to provide other functions do not need special equipment (such as the force device), it is difficult to achieve the universality of the tractor, multi-function. So, this approach has not been widely used.

At present, the widely used removable gooseneck low bed semi-trailer mostly adopts the semi-trailer and gooseneck with power equipment. Although the semi-trailer needs to be equipped with a lot of additional equipment, such as small gasoline engine, starter, battery, hydraulic pump, hydraulic cylinder, etc., but this way can improve the versatility of the tractor, to achieve the swing transport, so it is very widely used.

Besides using powered winch, hydraulic system, still can use from the tractor brake system of compressed air as the power source of the gooseneck disassembly, the advantage of this way is do not need to provide additional equipment, increase the weight of semi-trailer, also don't have to increase the corresponding maintenance cost, and low temperature in winter in remote places can be normal use.

In addition to the power removable gooseneck low flatbed semi-trailer, there is a kind of machinery that is generally used at present, namely the power removable gooseneck low flatbed semi-trailer. This semi-trailer is simple in structure and light in weight. Although it is necessary to modify the tractor and the loading and unloading process is more complicated, it is also widely used in long-distance transportation or heavy transportation.

Air or hydraulic removable gooseneck low bed semi-trailer cargo platform length is the shortest, heaviest weight, but the gooseneck disassembly speed, the most convenient and easy operation, the height of the cargo platform can also be adjusted according to the need.

The suspension system of the removed gooseneck low bed semi trailer

The removable gooseneck low bed trailer also has rigid suspension and elastic suspension. Rigid suspension is commonly used for heavy duty low flatbed semi-trailers with one-line biaxial and universal steering suspension mechanically removable gooseneck. Plate spring suspension cost is low, driving comfort is poor. Although the air suspension cost is high, but the driving comfort is good, can improve the service life of the frame, but also can be used to adjust the height of the cargo platform.

Hydraulic removable gooseneck low bed semi-trailer has ground bearing and non-ground bearing. When loading and unloading machinery and equipment on soft and muddy ground, the low bed semi-trailer in the form of ground bearing is easy to press the sleepers into the ground and cannot be removed, and it is difficult to lift the gooseneck. Non-ground bearing form of low bed semi trailer is suitable for various ground conditions, widely used. The removable gooseneck heavy-duty low-flatbed truck is usually used in conjunction with a towing platform to increase the front-end load capacity of the semi-trailer. At this point, the gooseneck length can either be adjusted by adding a turning gooseneck or using a retractable gooseneck, or the position of the traction pin can be adjusted. In addition, the reverse runner frame and the booster wheel frame can be added to improve the rear end bearing capacity of the semi-trailer.

The booster wheel stand is detachably connected to the rear end of the semi-trailer, which can be single, double or triple axles in order to provide a certain distance between the axles. Power assist wheel frame by three kinds of load transfer, that is, mechanical transfer, pneumatic transfer and hydraulic transmission. Mechanical connection of the power wheel frame can not be lifted up and down, pressure or hydraulic control of the power wheel frame can be adjusted by adjusting the pressure or hydraulic size to adjust the position of the power wheel frame, so as to obtain the desired bearing capacity or lift the wheel away from the ground a certain distance. The large wheelbase booster wheel frame can be steered for better steering performance.

When transporting a longer cargo, can use scalable loading of the structure of the detachable gooseneck low bed semi-trailer, also can use adjustable loading to wipe the sweat difficult detachable gooseneck low flat-panel semi-trailer (in half hanging wheel and front inserted between a loading goods to increase effective length, when not needed can be removed, in order to reduce the weight of semi-trailer). In the transportation of ultra-wide mechanical equipment, in addition to the transversially telescopic pallet structure, can also be installed on both sides of the frame trapezoidal pendulum support and springboard to increase the width of the pallet. After loading, the mechanical equipment is fixed by steel cables and soft belts through the holes on the secondary rail or the lifting rings welded on the outside of the frame. In order to reduce the height of the center of gravity, some removable gooseneck low bed semi-trailers also use trapezoidal cargo platform interface.

LEAVE A MESSAGE

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.

RELATED PRODUCTS

Xiamen Sunsky Vehicle Co.,Ltd has mature technology, rich experience, strong business capacity, broad market development, one year of free after-sales service.We specialize in exporting semi trailers more than 30 years.