Semi Trailer Suspension System

Automobile suspension is an elastic device that connects the frame and axle in the automobile. It is generally composed of elastic elements, guiding mechanisms, shock absorbers and other components, the main task is to ease the impact from uneven road to the frame, in order to improve the comfort of riding.

Suspension is an important assembly in the semi trailer, it connects the frame and wheel flexibly, relates to a variety of car performance. Viewed from the outside, car suspension is more difficult to achieve a perfect requirements of automobile assembly, this is because the suspension should not only meet the comfort requirements, and to meet the requirements of the steering stability, the two are only consists of a number of rod, tube and spring, but don't think it is very simple, on the contrary side is in opposition to each other.For example, in order to obtain good comfort, the need to greatly buffer the vibration of the car, so the spring should be designed soft, but the soft spring is easy to make the car brake "nod", accelerate "head up" and left and right roll serious adverse tendency, is not conducive to the car's steering, easy to lead to car operation instability.

Semi trailer suspension is an important part connecting semi trailer chassis walking device and frame. The vehicle's support force, braking force, driving force and so on are transmitted through the suspension system, and can also reduce the impact force of the bad road on the vehicle - shock absorption, to ensure the smooth of vehicle, its importance is self-evident. The following is a brief introduction of the semi-trailer on the four common suspension: steel plate suspension, air suspension, bogie suspension, rigid suspension.

- Steel Plate Suspension

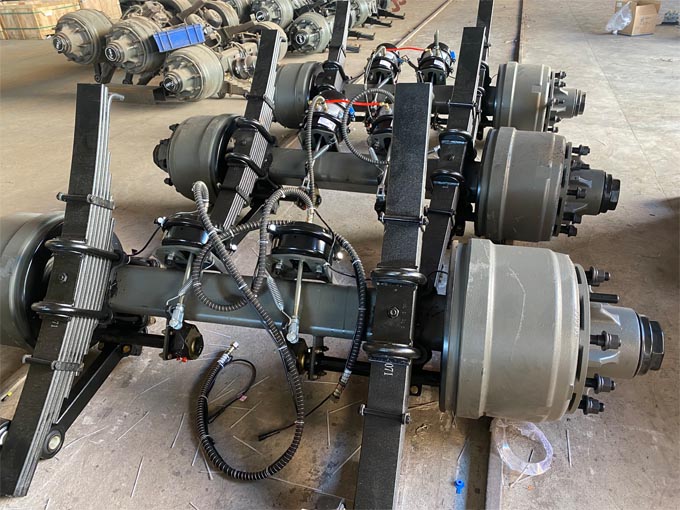

The steel plate suspension is common steel plate spring, the full name is the series type steel plate spring balanced suspension. It is mainly composed of steel plate spring, suspension support (commonly known as lifting lug), connecting rod, U-bolt and other parts. The biggest advantage of this suspension is cheap price, good reliability, easy maintenance, at present, more than 80% of ordinary semi-trailer in China is the use of steel leaf spring balanced suspension.

The leaf spring suspension can be divided into multi leaf spring and less leaf spring suspension.

1. Multi-plate spring suspension

(1) Advantages: simple structure, low cost, reliable work.

(2) Disadvantages: big dead weight increase the mass of the vehicle. Ride comfort, large layout space.

(3) Applicable models: heavy-duty models. At present, most of the models of SUNSKY are used in the suspension of multiple plate spring.

2. Less leaf spring suspension

The small plate spring suspension is composed of longitudinal small plate spring, two-way cylinder type hydraulic shock absorber, horizontal stabilizer bar, buffer block and other components, and the composition of the multi-plate spring suspension is basically the same.

(1) Advantages: the front suspension with less spring, less spring has the characteristics of equal stress, small friction between the pieces, reduce the weight of the vehicle, to meet the trend of vehicle lightweight. It improves the ride comfort of the vehicle and the driver's comfort. Reduce noise.

(2) Disadvantages: the processing of variable cross section less leaf spring requires a high level of industry.

(3) Applicable models: light load models.

- Air Suspension

I believe you are not unfamiliar with the air suspension, air suspension is simply to air spring as the elastic element of the suspension, the most obvious characteristic is the air bag type of air spring, because of its different types of structure is very different, here is not introduced in detail.

What are the advantages of air suspension? What are the common failures?

Advantages of air suspension:

1. Light weight. The biggest advantage of the air suspension is its light weight, much lighter than the traditional leaf spring suspension. This is also an important reason for ordinary users to pay attention to the air suspension. Under the premise of the current weight charge, the air suspension has obvious lightweight advantages.

2. Convenient loading and unloading.Through the manual height valve in the air suspension system, the height of the vehicle loading platform can be adjusted within a certain range to facilitate loading and unloading of goods.

3. Smooth running, good shock absorption performance.Compared to lightweight vehicles, vehicles equipped with air suspension can run more smoothly. The elastic coefficient of the air spring is that the soft and hard spring can be adjusted automatically according to the need. When the vehicle is running at high speed, the air spring will harden to improve the stability of the vehicle, and when it encounters poor road conditions, the air spring will become soft to improve the comfort of the vehicle. Through the adjustment of the air spring can also ensure that the height of the car is constant, conducive to the protection of the safety of the goods.

4. High security.The uniform distribution of the axle load and the balanced contact between the tire and the ground can improve the overall braking performance and turning stability of the axle. At the same time, the height of the air spring can be automatically adjusted according to the road conditions, reducing vibration, which is conducive to protecting the safety of goods.

5. Reduce maintenance costs.When the vehicle is running without load, the air suspension can lift the axle, reduce tire wear, extend the service life, and reduce fuel consumption.

The most common fault of air suspension is that the air bag is airless or the air bag is wrinkled. The reasons for these two situations are different, and the treatment method is not the same. It should be treated differently when actually encountered.

1.All the air bags are empty

This situation is relatively easy to check, as long as we understand the structure of the air suspension. The air source of the air suspension is connected out by the brake system, through the pressure protection valve, and stored in the special air storage cylinder. Work through the filter to the core component of the air suspension - height control valve, and then to the left and right air bags.

The reasons for this may be:

(1) The special air storage cylinder for air suspension is airless or the pressure is very low. In order to ensure that the braking system has enough pressure, when the trailer pressure is lower than 0.6Mpa, the pressure protection valve will stop supplying air to the air suspension air storage cylinder.

(2) The air pipeline is blocked or discounted, but gas.

(3) The connecting rod of height control valve falls off.

(4) Height control valve damaged.

Solutions:

(1) Adjust and replace the discounted and blocked trachea.

(2) Adjust the installation height of the control valve connecting rod.

(3) Replace the height control valve.

2. The air bag is inflated but the air bag is wrinkled

The reasons for this may be:

(1) When the vehicle is transported and hoisting, the air bag is stretched out more, and it is not restored normally, leading to the wrinkle of the air bag.

(2) When the vehicle is in and out of the maintenance workshop or a large slope, it may also lead to individual airbags being overstretched, resulting in airbag wrinkles.

Solutions:

Disassemble the connection between the rubber connector and the axle below the vertical pole of the height control valve, lift the rod upward, and so on. After all the air bags are fully inflated, then install the rod back, and the air bag can return to normal state. In addition, such as the frequent occurrence of this fault in the process of driving, it is necessary to consider increasing the limit device between the axle and the frame.

3. Tractor and semi-trailer braking is not synchronized, resulting in vehicle braking jump

The reasons for this may be:

Vehicle parking or reverse braking, due to the inertia of the vehicle, the braking moment, vehicle tail will stretch up, to carry out a handbrake brake at the same time, the vehicle tail will not be able to fall, height control valve in the exhaust state at this time, air pressure will be empty, when loosen the brake again, the vehicle will be instant or cause balloon fold whereabouts.

Solutions:

(1) Parking or reversing the vehicle slowly to stop and then pull the handbrake, the above situation will not occur.

(2) If the air bag appears wrinkled, loosen the connecting bolt between the height control valve and the axle, inflate the air bag completely, and then install the connecting rod back in the original position.

- Rigid Suspension

The left and right wheels of the rigid suspension are connected by an axle, and the weight wheel is directly fixed on the body of the car without the use of springs. The most commonly used rigid suspension is the axis suspension, which has two lines and four Bridges, three lines and six Bridges, etc., which is mainly suitable for low-speed carriage of goods on the axis low bed semi-trailer and concave beam trailer. Its damping effect is poor at high speed.

- Bogie Suspension

Bogie suspension is the common plate spring before and after the bracket is reduced to a single bracket connected to the car body, the ordinary semi-trailer used less, compared to the ordinary plate spring suspension, bogie suspension bearing capacity is larger, mainly used in heavy vehicles.

- Postscript

Of course, the type of semi-trailer suspension can be not only these, this paper is only a simple introduction of several common semi-trailer suspension, so that we have an understanding. In recent years, a very popular word in the commercial car industry is "lightweight". A very important part of the lightweight body is the suspension. At present, it is more popular to replace the multi-leaf spring structure with less leaf spring. But the suspension itself also has an important factor is load-bearing, which means that the number of spring plates should be reduced while taking into account the body bearing capacity. Therefore, the balance of the number of spring plates and carrying capacity has become the biggest facing problem to manufacturers.

Leave a Comment